INVERCLYDE SHIPBUILDING

Fergusons

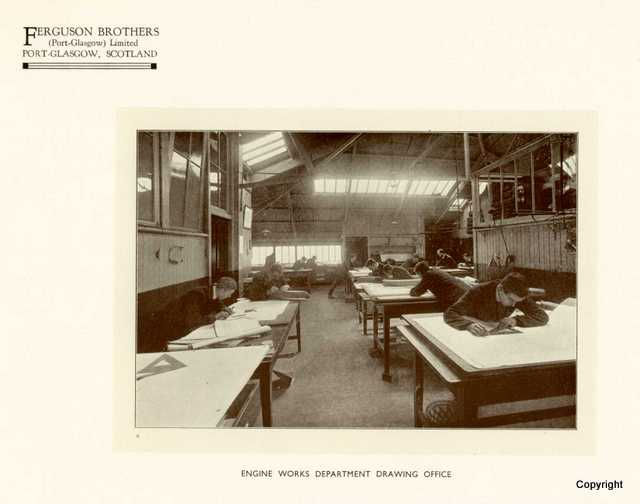

The four Ferguson brothers Peter, Daniel, Louis and Robert broke away from their father’s company of Fleming & Ferguson Shipyard at Paisley and set up on their own as consultants in the Baltic Chambers, Glasgow, on October 15th, 1902. Apart from Daniel all held executive at Paisley before leasing from Messrs W Hamilton the Newark Shipyard, Port Glasgow, at £500 per year securing in January 1903, when they obtained an order an order from Clyde Shipping Co. Ltd. for the building of two steam tugs. The yard numbers of these vessels being 153 and 154, FLYING SWIFT and FLYING LINNET, which were engined by Muir & Houston. By the third vessel SIR HARRY BULLARD they had their own engine building facilities, their key men coming from Paisley, the workforce building up to 400 and producing up to seven dredgers per year. About 1907 the site was purchased from W Hamilton the name changing in 1912 to Ferguson Brothers(Port Glasgow) Ltd following the death of Daniel from pneumonia. The First World War saw the firm producing 29 vessels comprising minesweepers, trawlers, hospital ships, and were the leading builder and designer of the Sir David Hunter Class and Rescue Class Admiralty tugs. They also built the bucket ladder dredger PONRABBEL in 1913 for Tasmania which was sunk by the German raider EMDEN in the Indian Ocean on her delivery voyage. Another wartime casualty was the new yard office, destroyed by fire in 1914 despite having a fully functional sprinkler system linked to the town reservoir which had been shut down for the night, all the company records being lost. During the 1920’s only the manager was employed to clear the weeds, shoot the pigeons and tend the tomato plants which seeded themselves at high water mark. Becoming linked to Amalgamated Industries after the First World War in 1919 and sold to the John Slater Group of London in 1921 but returned to the Ferguson Brothers in 1928 when they built DISCOVERY II for service in Antarctic waters.

The Second World War saw the company producing 30 ships including tunnel tugs, minesweepers, corvettes, Turkish ferries and boom defence vessels. By 1947 the Company Directors were Peter Ferguson, Louis Ferguson, Robert Ferguson and Peter Williamson. On the premature death of Mr. Bobby Ferguson in 1954, Lithgows purchased a minority interest in 1955 and obtained full control in 1963. In 1969 Ferguson Brothers became part of the Scott-Lithgow Group and on 1st July 1977 a member company of British Shipbuilders. In 1980 the yard amalgamated with the Ailsa yard at Troon, thus forming Ferguson-Ailsa within British Shipbuilders. In 1986 the Troon yard was sold to Ailsa Perth leaving the Port Glasgow yard to join with Appledore Shipbuilders to form Appledore Ferguson Shipbuilders.

On Tuesday, 26th September, 1989, the yard was sold to the Greenock engineers Clark Kincaid and became part of the HLD Group. The Norwegian Kvaerner Group acquired a majority shareholding in HLD in January 1990 who sold the yard to Ferguson Marine plc in March, 1991, for £225,000; the company being established by Mr. AR Belch in association with Mr. W Scott, Sir Ian Denholm, Mr. R Parkinson and Mr. G Parham. In July 1995 the 290 shareholders accepted Holland House’s bid of £4.9 million, with Mr. F Dunnet, Chairman, and Mr. A Dunnet, Chief Executive, resulting in the demise of the previous Board and the appointment of Mr. R Deane as Director/General Manager and Mr. J Findlay as Operations Director. On take-over from British Shipbuilders in 1989 the workforce has grown from 35 to 375 today. Since 1903 over 340 vessels have left the slipways at Port Glasgow for all over the world.

J Craig Osborne 3-5-2001

Yard Facilities

The yard comprises an open building berth with unit fabrication sheds on east and west, a preparation shed, pipe fabrication and joiner’s shops, fitting-out quay, general store, sawmill and offices.

Building Berth

Constructed 1982/4 and formed of reinforced concrete 40 metres wide and capable of accommodating vessels up to about 100 metres in length overall with generally two vessels alongside. Craneage is provided by a Potain travelling tower crane having a lifting capacity of 6/16 Tonne at 45/19.4 metre radius. Other services include 440v electricity, Oxygen, Propane and Fire extinguishing. Units are transported within the yard using a tractor to pull 15 and 45 Tonne trailers. Small loads are lifted using 2.5 and 3.5 Tonne fork lift trucks while two mobile cranes of 45 and 75 Tonnes cater for the larger loads.

East Fabrication Shed

Converted in 1963 from an engine building and machine shop and situated to the east of the building berth and divided into two bays running north/south, 70 metres long and 35 metres long giving a total area of about 1575m2 . The longer bay being served by a 12.5 Tonne and a 20 Tonne overhead crane, the smaller bay having a 25 Tonne overhead crane. Both bays are fitted out with the usual electrical and gas services.

West Preparation and Fabrication Shed

Constructed in 1981 and situated to the west of the building berth and divided into two bays running east/west, 85 metres and 110 metres long giving a total area of about 3400 m2. The small shed, which is utilised for small fabrications and preparation work with the west end being used to store bars and sections, is fitted out with two 10 Tonne overhead Matterson cranes, Hancock bar/plate burning machine(4 heads with optical control), Hugh Smith 200 Tonne cold frame bender and a 1,000 Tonne plate roller catering for plates up to 10.9m long and 32mm thick. The longer shed, adjacent to the river, is utilised for fabrication at the east end and is fitted out with panel line welding, single sided butt welding station, 2.4m Keetona Guillotine, 2.4m SMT plate mangle machine, Pearson 500 tonne Flanging Machine for plates up to 3m long and 12mm thick, Messer Griesheim Plasma & Gas NC machine capable of burning plates up to 8/17m long and 25/100mm thick respectively, the west end being used for plate storage, all of which is served by three overhead cranes of 3, 10, and 15 tonne capacity.

Fitting Out Quay

Built in 1995 and arranged in two parts, a 90m long face parallel with the river and a 50m long face adjacent. The 90m face is served by a 2.4/8.0 tonne at 36/12.7m radius travelling tower crane. The quay is designed for a UDL of 3 tonnes/m2 and can accommodate concentrated loads of up to 126 tonne utilising crane matts of 3m x 2.5m. Eight – 30 Tonne mooring bollards are fitted along the face. The quay face was dredged in 1995 to 5m below chart datum up to 25m off the face of the quay.

Pipe Fabrication Shops and Ferguson Hydraulics

Created in 2,000 this 45m x 15m shop is fitted out with two pipe bending machines, grooving, flaring machines and served by a 5 tonne overhead travelling crane. High and low pressure hydraulics are fabricated by Ferguson Hydraulics in a separate shop built in 2,000 outfitted with pipe bending and testing facilities.

Newark Joiners

Created in 1992 this shop makes all the furniture for the vessels and fits the linings, divisions, insulation, doors etc.. on the vessels.